Due to our stellar reputation for engineering, we have been chosen as the sole uk & ireland distributor for overmat liquid screed and eps trucks

We have just secured the sole UK distributorship for the Overmat Liquid Screed and EPS systems. We will take care of the sales of these machines, but most importantly the servicing and maintenance from our 20,000 square foot factory in Dinnington, Sheffield.

Is the prospect of having to wait months for spare parts and repairs dissuading you from buying a liquid screed truck? Worry no more, we’re here to help, we stock spare parts in our warehouse and are on hand for any repairs needed when required, our central base in the country means you are never too far away from us.

Our 20,000 square foot factory

Overmat has become a key player in the research and development of solutions for improving construction industry operations. Their systems enable the precise, efficient and rapid production of the widest range of materials required for the floor finishes needed on construction sites, whether they be base slabs or screeds for flooring. IHS UK LTD will support you throughout the life cycle of the machine, ready to offer you advice and information aimed ay achieving the maximum performance of your Overmat system. We are aware of the importance of after sales service that supplies the spare parts in a short time; for this reason we keep out warehouse stocked ready to supply to you, the customer.

Simplified logistics and greater profit

REDUCTION OF CONSTRUCTION SITE COSTS

Thanks to the use of loose materials, stored in the specific compartments of the machine.

NO WASTE

The material is perfectly dosed and what is not used remains inside the machine, ready to be used on the next site. You therefore have no waste or packaging to dispose of.

NON-STOP WORK

You can work even in bad weather, the materials are protected from atmospheric agents

LESS EFFORT FOR THE OPERATOR

Pumping mixing takes place continuously and automatically. Your presence on the machine is not necessary, the entire work cycle is managed from the ground by radio control.

AGILITY AND COMPACTNESS

You can operate on multiple sites throughout the day.

Compared to the so-called “traditional” working methods, the construction site is completed in half the time.

Overmat Products

Traditional sand-cement screeds and premixed screeds

An OVERMAT T series system is the ideal solution for the production of traditional screeds and premixed screeds.

This system is compact and has an extremely low center of gravity thanks to the liftable barrel. The barrel remains protected during travel and this allows for the creation of all the products requested by the client.

The system remains constantly in a horizontal position and realizes your recipes with maximum versatility.

Powerful software allows you to control all dosages accurately. From aggregates of different granulometry, to binders, to additives (both liquid and gel), to fiber additions.

The whole process is recorded in the computer memory. It can be exported either via a convenient USB key or on the internet, via the data SIM installed on board

This system is also available in the version for the production of dry premixed screed.

Self-leveling screeds made with precision

An OVERMAT ALS series system is the ideal tool for creating self-leveling screeds with extreme precision.

This machine is the most compact in its category, thanks to the flat bottom sand silo it unloads onto the belt. The center of gravity is remarkably low thanks to the liftable pump tank, which remains protected while traveling. This allows to realize all the products that are requested by the client.

The system is fixed in a horizontal position and realizes your recipes with maximum versatility and precision.

Thanks to a powerful and intuitive software it is possible to control all dosages accurately. From aggregates of different granulometry, to binders, to additives (liquid, gel or powder), to fiber additions.

Using the sand humidity measurement probe, the computer automatically corrects the quantity of water for each load. The slump of the product is always perfect, guaranteeing unparalleled resistance and workability.

All the parameters, from the loading order of the recipe to the mixing times, are programmed on site in a simple and intuitive way. The whole process is recorded in the computer memory and can be exported either via a convenient USB key or on the internet, via on-board data SIM.

To produce pre-mixed self-leveling screeds and lightened substrates

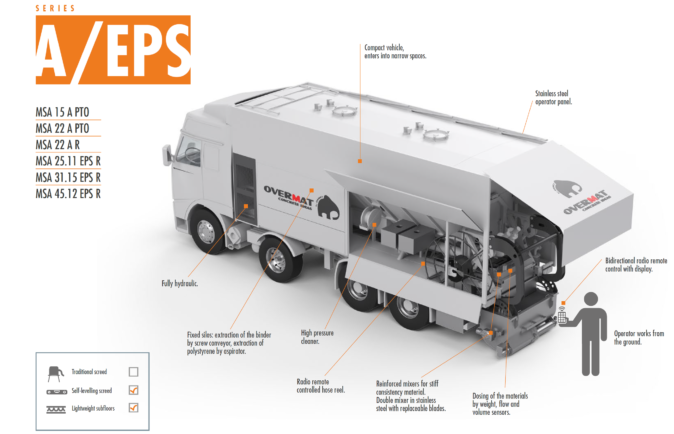

An OVERMAT A / EPS series system allows the production of lightened substrates and pre-mixed self-leveling screeds with great precision and ease.

The plant is fully automated. Thanks to its versatility, it allows the operator to produce insulating mixtures with 100% foam (without inert) up to mixtures with 100% light inert (without foam), with all the intermediate possibilities.

Thanks to the double rear mixing tank, the plant doses all the components in the first mixer. It then homogenizes them in the second mixer and adds foam to the third (static) mixer , when required.

The whole process is continuously monitored by the on-board computer, for constant quality, through a series of closed-loop controls. All the working parameters are set by computer and are constantly measured and corrected in real time. To guarantee a product consistency that is unparalleled.

By storing each single load carried out, it is possible to certify the work carried out. All this according to the requests of the most demanding and prepared clients and to make the stored data available on a web archive.

Click here to learn a little bit about Overmat and we’re sure you’ll see why we teamed up with them, we believe they give the best solution for making liquid screed and EPS on site.

Get in touch to learn more or to buy your new truck today